With ebos®, we have developed a software product that combines a wide range of features with the simplest user guidance and thus becomes a significant, innovative tool for manufacturing facilities.

A specific industry solution that precisely covers the needs of precast concrete production. Complex interrelationships are clearly visualized and can be seen at a glance.

Via the mebosyc mobile application, you can keep an eye on production from anywhere. Data is stored centrally and a paperless factory is guaranteed.

Your Benefits

Complex correlations are clearly visualised at a glance

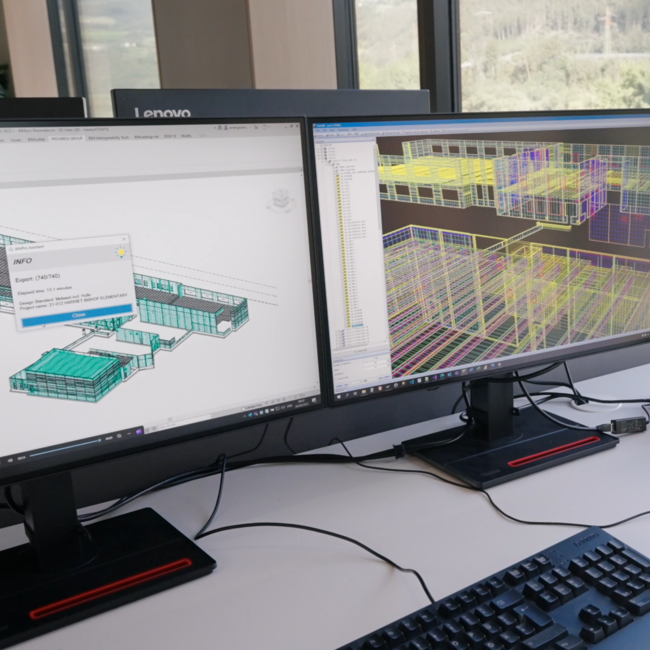

3D visualisation of the carousel plant with real-time information

Simple handling and high usability

TRANSPARENCY & PRODUCTIVITY

GRAPHICAL PERFORMANCE ANALYZER

With ebosyc a new era of carrousel control has begun! An innovative 3D visualization of the carrousel plant makes it even easier to keep an eye on production. Through an open cloud technology, it is not only possible to visualize it in the production office, but from anywhere.

This opens up whole new worlds in production control and analysis.

OPTIMAL PALLET ASSIGNMENT

With the help of ebos® pallet assignment, the concrete elements are automatically or manually placed optimally on production pallets. Use your capacities and increase the productivity of your plant automatically. ebos® shows you how to place most efficiently.

EFFICIENT PRODUCTION

The Dynamic Smart Production solution provides your employees with exactly the right information at the right time. Thanks to our intuitive interface, everyone involved always stays on the same page. You maintain an overview and increase the efficiency of your precast production at the same time. Targeted visualization of production data gives you more transparency and control over your production while minimizing the need for rework.

Say goodbye to inefficient, paper-based processes and take the first step towards digital transformation.

AUTOMATED QUALITY CHECK

The ebos® Quality Check module offers the possibility of fully automatic image capturing of the finished or semi-finished element at certain stations. Automated overlay can be used to confirm the quality check very easily.

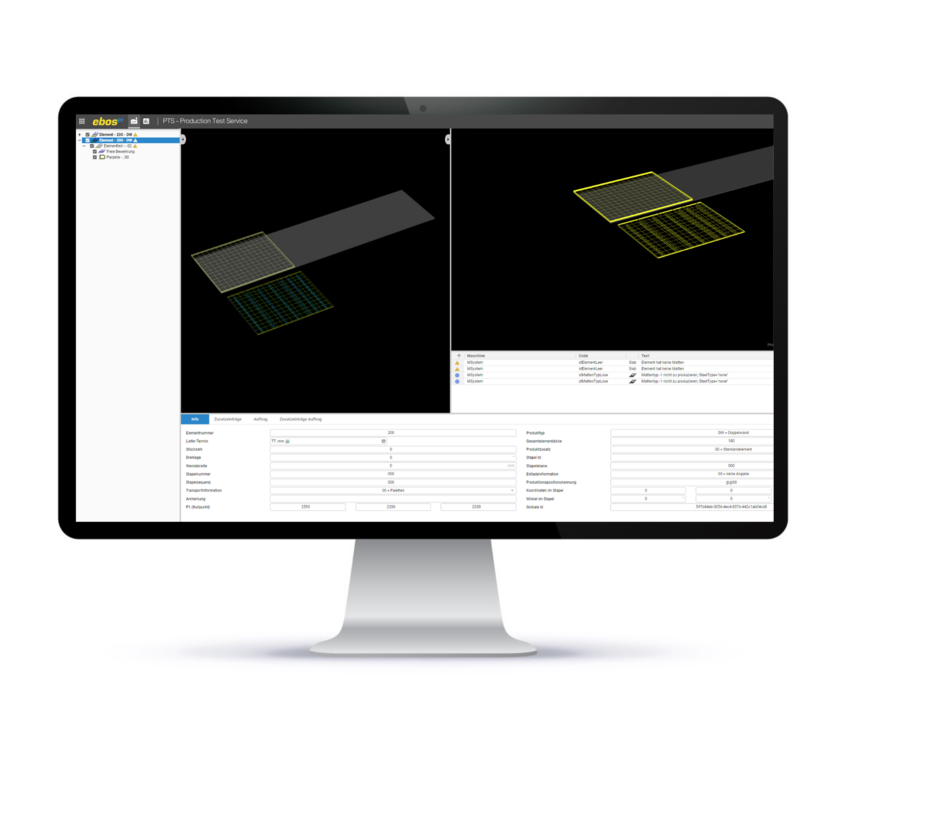

PRODUCTION TEST SERVICE

The fully featured PTS-client in the ebos® system checks the production data in the work preparation process for correctness. Both in terms of producibility and in terms of production optimization. This minimizes sources of error, prevents production downtimes and avoids changes to the machine. Increased efficiency guaranteed.

REFERENCES, WHICH SPEAK FOR THEMSELVE

"We chose progress because we were convinced of the type of control unit and system."

Max Bögl Group - Christian Rackl, Production Manager at the Sengenthal precast plant

"A prerequisite for high performance with calculable accuracy are machines and software solutions, which on the one hand can be optimally integrated into our existing plant and on the other hand contribute to a targeted increase in efficiency"

Orion Beton - Tonny Bunte, Project Manager