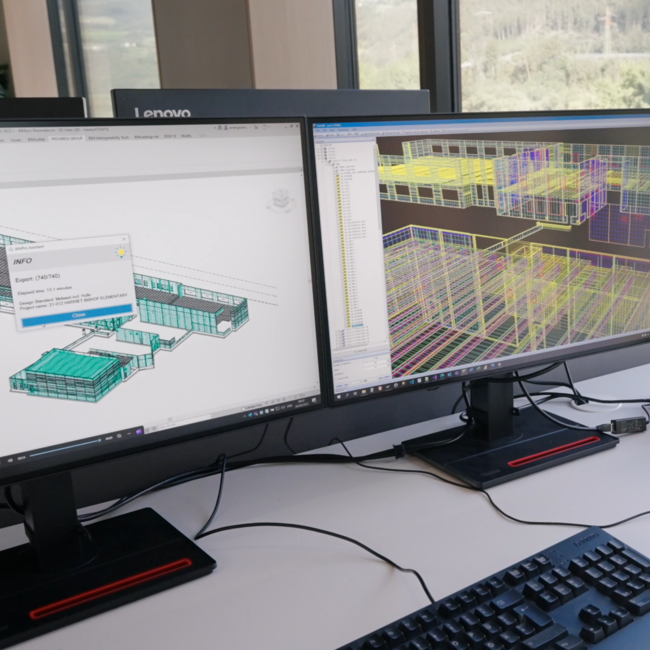

Software for rebar processing

The MES-systems profit & steelbos monitor all production processes and machines to achieve maximum accuracy and efficiency in rebar processing.

profit & steelbos are versatile software solutions for organizing and managing rebar shops and, with deep machine integration and open data interfaces, deliver the perfect solution for bending shops, even with existing machines and other software solutions. Also complex logistics can be controlled easily.

Your benefits

Deep machine integration for maximum accuracy in production

Automated producibility test of the data for smooth production

Visual and simple production overview, traceability & logistics handling

DESIGN

DesignPackage

What you design is what you get. That's why a design package is integrated to easily and quickly create mats and baskets with predefined templates.

Webshop

Your customers can use the webshop to plan stirrups and baskets, check them for producibility, send them to your bending store and follow the production.

PTS-Check

With our Production Test Service, you can automatically check if what you have designed can be produced by your plant.

PRODUCTION

Detailed production planning

The utilization of the machines is analyzed in real time, the processed data is automatically scheduled for production and sent to the machines.

Data adaptation

Imported data is automatically adapted so that it can be optimally produced by the machine. This avoids production downtime and ensures a seamless production process.

Seamless data transfer

profit can exchange data very flexibly and comprehensively with higher-level ERP systems and any machines.

LOGISTICS

steelbos is a special feature to digitally support rebar shops in logistics.

steelbos enables:

- control of driverless transport systems

- just-in-time updates for logistics processing

- tracking of elements

- warehouse management

The entire steelbos system is also optimised for rebar shops with carousel plants: bottlenecks can be predicted and monitored using a graphical performance analysis to achieve greater efficiency in production.

With the mobile application easier and more intuitive use of the system is guaranteed.

MONITORING

Status overview

The real-time data flow means you always have an eye on the current production status. Delays or bottlenecks are thus easily detected.

Material traceability

Easy material traceability and stock management for coils and bars are no longer a problem in profit. Each cut iron can be assigned to a batch.

Machine feedback

All production data is collected centrally and helps to increase the productivity of the plant. Maintenance planning is also significantly simplified. Thanks to networking with all machines, the system plans maintenance efficiently and self-learning, with independent suggestions.

WorkloadProfiler

The WorkloadProfiler provides an overview of the current utilization of all machines. Through machine learning, the duration of production jobs can be predicted.